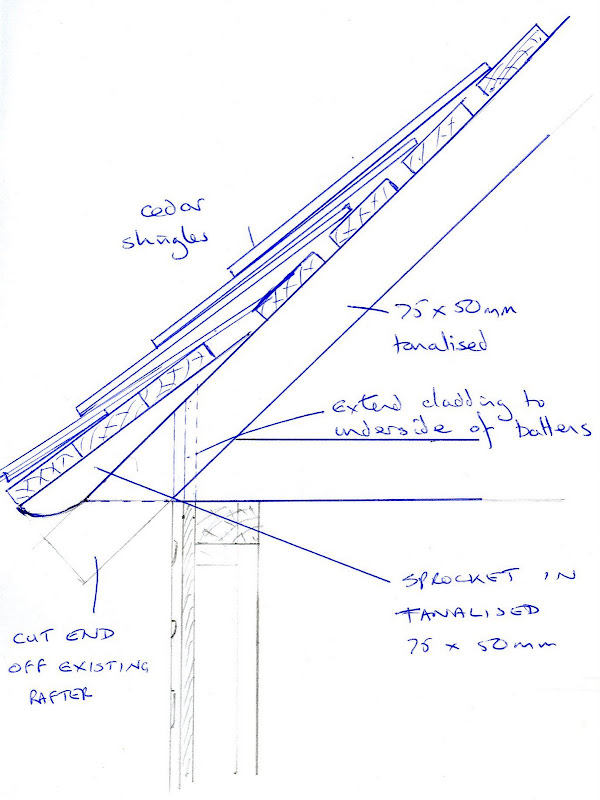

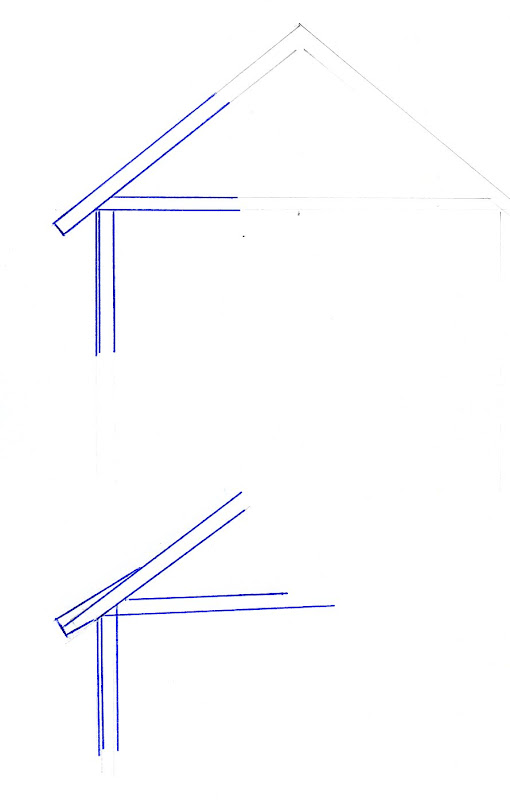

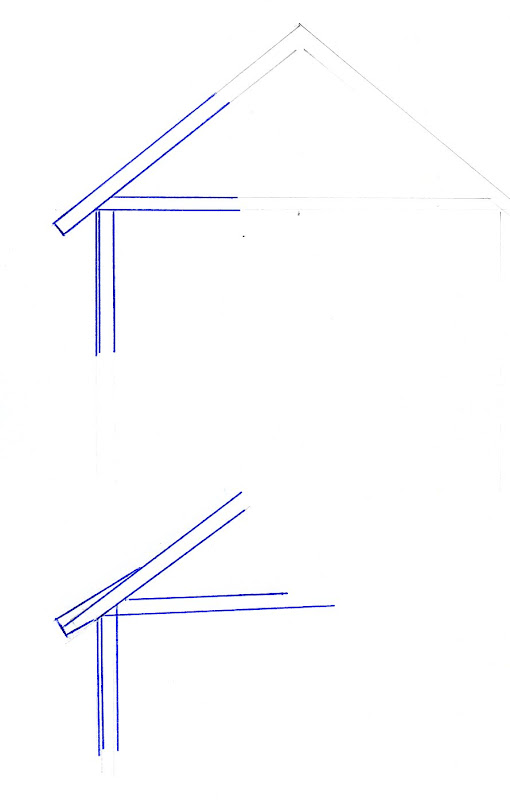

I was intrigued to read about the subject of sprockets and the "kick" that they give to the lower roof slope in Colin's excellent shed build thread. , and was wondering whether this is this something that would suit a more conventional approach? I have just started a project for a shed with a New England style "saltbox" roof which will be covered with cedar shingles. The original plan calls for a simple rafter as in the top sketch below, but could it perhaps be amended as shown in the lower sketch to provide a "kick" to the first 3 courses of shingles? Again, the plan calls for a simple fascia and soffit attached to the end and underside of the rafter, so would installing a "kick" require a different approach to the way the ends of the rafters are treated?

Rafters are in 75 x 50mm tanalised and the shed will be clad in shiplap. The trusses are already built but not yet installed so if there are going to be any changes they need to be done now.

This is a picture of what I've been trying to emulate, but also like the idea of a kick to the lower roof slope provided that it enhances the overall lines. If it doesn't, I might as well just build it as shown.

[/img]

[/img]

Rafters are in 75 x 50mm tanalised and the shed will be clad in shiplap. The trusses are already built but not yet installed so if there are going to be any changes they need to be done now.

This is a picture of what I've been trying to emulate, but also like the idea of a kick to the lower roof slope provided that it enhances the overall lines. If it doesn't, I might as well just build it as shown.